Foam Inserts for Boxes The Smart Choice for Product Safety

Introduction

In today’s fast-paced business environment, packaging is no longer just about getting products from point A to point B. It’s about safety, presentation, sustainability, and customer experience. One of the most effective yet often overlooked solutions is foam inserts for boxes. These inserts provide superior protection, enhance the unboxing experience, and help businesses cut costs by reducing damage during transit.

Among the most popular materials for protective packaging are polyurethane and polyethylene packaging. Both offer unique benefits, and when combined with thoughtful design, they create tailored solutions for industries ranging from electronics to healthcare.

This article explores how foam inserts are reshaping packaging, the role of polyethylene packaging in sustainable practices, and why businesses are switching to smarter solutions.

1. What Are Foam Inserts for Boxes?

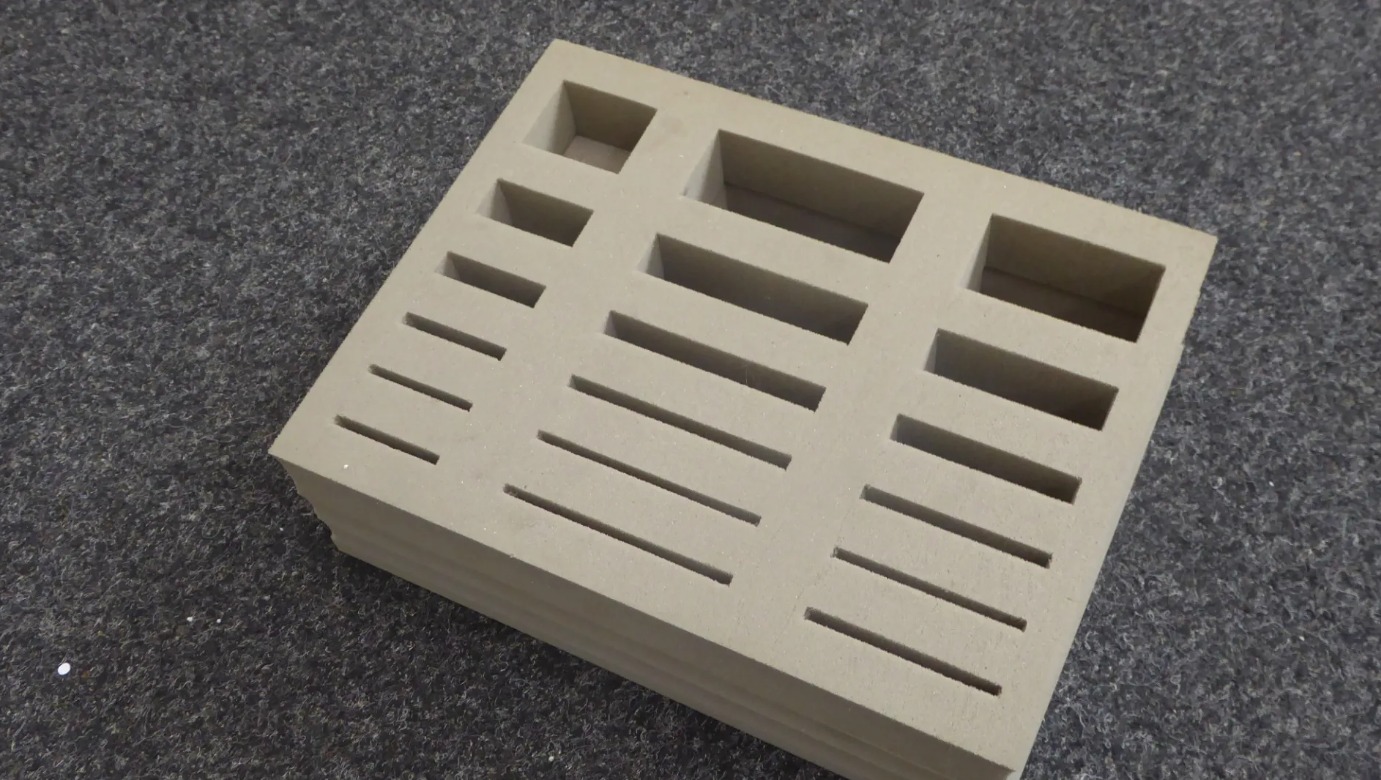

Foam inserts are custom-cut or molded foam pieces placed inside boxes to protect products during transport and storage. Unlike generic fillers such as shredded paper or bubble wrap, foam inserts are tailored to the product’s exact dimensions.

- Precision Fit: Items sit securely in place without moving around.

- Shock Absorption: Foam absorbs vibrations and impacts, reducing the risk of breakage.

- Professional Presentation: Products look organized and premium when unboxed.

For fragile, high-value, or multi-component items, foam inserts offer a level of safety and elegance that standard packaging materials cannot match.

2. Polyurethane and Polyethylene Packaging: What’s the Difference?

Polyurethane Packaging

Polyurethane foam is flexible, lightweight, and resilient. You’ve likely seen it in bedding and furniture, but it’s also widely used for packaging delicate products.

- Ideal for lightweight or multi-product packaging.

- Often used in “egg box” form with peaks and troughs that hold items securely.

- Suitable for fragile items such as ceramics, jewelry, medical instruments, and computer parts.

Polyethylene Packaging

Polyethylene foam, on the other hand, is denser and provides stronger protection. It’s commonly used when products require shock absorption and scratch resistance.

- Excellent for electronics, automotive parts, and industrial tools.

- Water-resistant and dust-free, making it suitable for long-term storage.

- More sustainable due to recyclability and reuse potential.

Together, polyurethane and polyethylene packaging provide versatile solutions that can be customized depending on product type and shipping requirements.

3. Industries That Benefit from Foam Inserts

Foam inserts for boxes aren’t limited to one sector. In fact, they are highly adaptable and used across multiple industries:

- Electronics: Protecting sensitive gadgets, components, and circuit boards.

- Jewelry: Preventing scratches and ensuring luxury presentation.

- Medical Supplies: Safeguarding delicate instruments and pharmaceutical items.

- Ceramics & Glassware: Minimizing the risk of cracks and chips.

- E-commerce: Enhancing unboxing experiences and reducing returns due to damage.

The versatility of foam packaging means it can be applied to almost any product that requires extra care during handling and delivery.

4. The Benefits of Foam Inserts for Boxes

a. Maximum Protection

Foam inserts are designed to absorb impact and reduce movement inside the box. This makes them particularly effective for shipping fragile and expensive goods.

b. Customizable Design

From size and shape to color and density, foam inserts can be customized to match your exact product and branding needs.

c. Cost Savings

While foam packaging might seem like an added expense, it reduces product returns and replacements, ultimately saving businesses money.

d. Professional Appearance

Custom foam inserts enhance the look and feel of your packaging. Customers receive products in pristine condition, which boosts brand reputation.

e. Sustainable Options

With increasing demand for eco-friendly solutions, many suppliers now offer recyclable polyethylene packaging options, reducing environmental impact without compromising protection.

5. Sustainability in Packaging: A Growing Priority

The packaging industry is undergoing a transformation. Businesses are under pressure to reduce waste and adopt eco-friendly alternatives. Foam inserts and polyethylene packaging fit perfectly into this shift when designed thoughtfully.

- Reduced Material Waste: Custom-fit foam means less reliance on unnecessary fillers.

- Recyclable Materials: Polyethylene foam can be recycled or reused multiple times.

- Smaller Boxes, Lower Carbon Footprint: Tight-fitting packaging allows for smaller boxes, which leads to more efficient shipping.

Companies like Advanced Protective Packaging in Manchester are leading the way, offering bespoke foam solutions that balance protection with sustainability.

6. Why Businesses Are Choosing Local Packaging Suppliers

Working with a local packaging supplier has clear advantages:

- Faster Lead Times: Quick turnaround for orders and replacements.

- Lower Transport Emissions: Reduced shipping distance = smaller carbon footprint.

- Personalized Service: Local suppliers often offer custom consultations and tailored solutions.

For example, a Manchester-based company not only supplies foam inserts and polyethylene packaging but also provides complementary products such as corrugated boxes, bubble wrap, and packaging tape. This “one-stop-shop” approach simplifies procurement and ensures consistency across packaging solutions.

7. How Foam Inserts Improve the Customer Experience

In the age of e-commerce, the unboxing experience matters just as much as the product itself. Foam inserts for boxes play a big role here:

- Neat Presentation: Products arrive arranged and secure.

- Brand Perception: Premium packaging increases perceived product value.

- Customer Loyalty: A positive first impression encourages repeat purchases.

Today’s customers expect both protection and aesthetics, and foam packaging delivers on both fronts.

8. Practical Applications of Polyethylene Packaging

Polyethylene packaging isn’t just about protection; it’s also about efficiency and adaptability. Some of its practical uses include:

- Toolkits and Case Inserts: Dense polyethylene foam with cutouts for each tool.

- Medical Equipment: Sterile, dust-free storage for surgical instruments.

- Industrial Products: Heavy-duty inserts that withstand weight and pressure.

- Retail Displays: Custom foam displays for cosmetics, gadgets, and luxury goods.

Its durability and reusability make polyethylene packaging an excellent long-term solution.

Conclusion: The Future of Foam Inserts and Sustainable Packaging

As businesses navigate rising customer expectations and environmental responsibilities, packaging solutions like foam inserts for boxes and polyethylene packaging are becoming essential. They strike the perfect balance between protection, presentation, and sustainability.

Whether you’re shipping fragile electronics, luxury jewelry, or sensitive medical tools, foam inserts ensure that your products arrive safely and in style. At the same time, polyethylene packaging offers eco-conscious businesses a pathway toward greener operations.